Process Tab

This area is used to set reprocessing parameters, requirements, and special instructions of the item. The information will be displayed upon scanning the tray at certain points in the reprocessing workflow. It also provides some printing options.

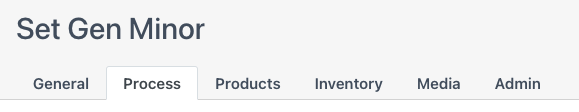

Decon Area

This area is used to set a workflow and instructions for users when this item is in Decon. When the item is scanned, this information is displayed.

Method

This area sets instructions for workflow upon scanning this item to decontamination.

Decon Special Instructions

Enter any additional free text information.

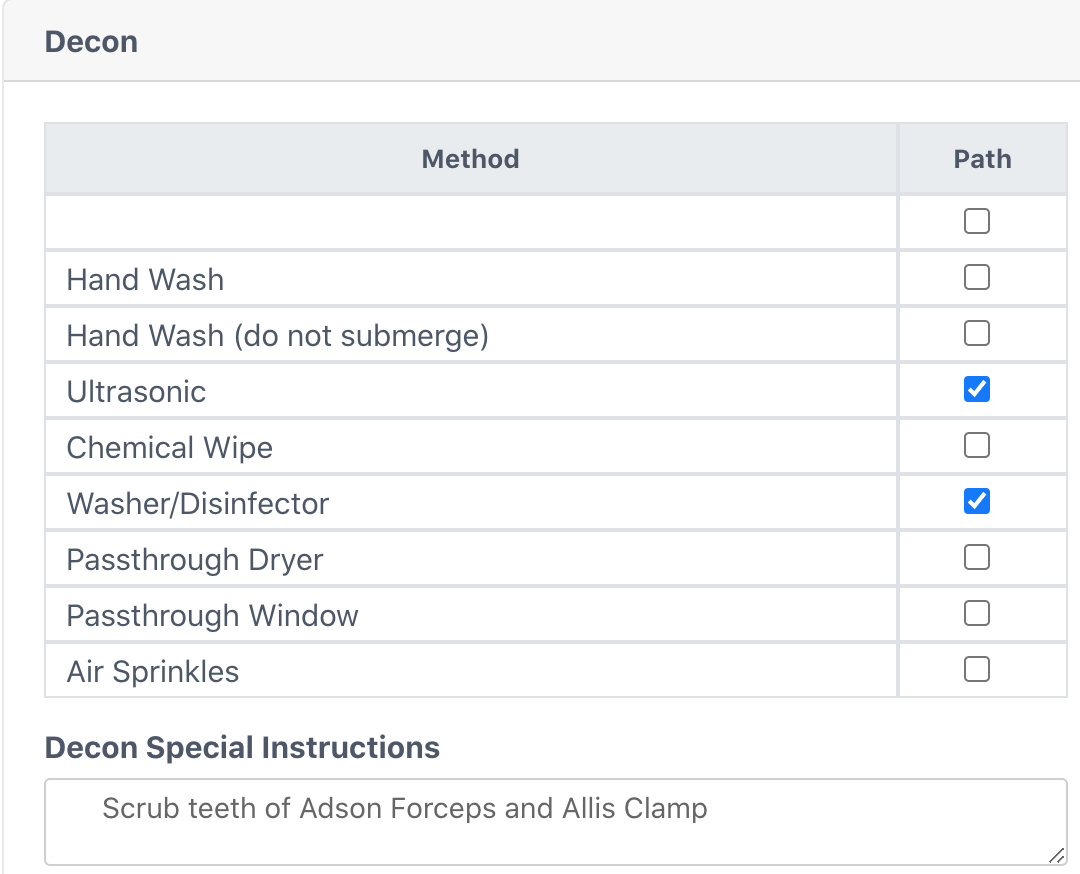

Assembly Area

This area is used to set workflow, instructions, and restrictions when this item is in assembly.

Reverse Assembly

Select to show all products as found when scanning this item in assembly . The user will not have to check off the instruments. The user is still able unmark instruments to set them as missing.

Requires Double Check to Print

Select to require a "double check" scan from another user other than the assembler to acknowledge it has been assembled properly. For more information regarding user access to printing production/permanent labels for items, visit Access to Printing Item Labels.

Difficulty Bar

Sets a difficulty level on a tray in the assembly process. A user without credentials for this difficulty level or above will be blocked from assembling this item.

Alt Production Labels

Select to assign a production label to print for the item that is different than the default at your facility - it may be a different size or different formatting.

Don't Print Count Sheet

Select to prevent the automatic printing of a count sheet upon finishing this item in assembly. This can be used for items that don't have a count sheet built out, like a Vendor Set.

Generic

Select to make this item generic. For more information on a generic item, visit Generic Pack.

Assembly Special Instructions

Free text field for any special instructions that will show up while a user assembles this item.

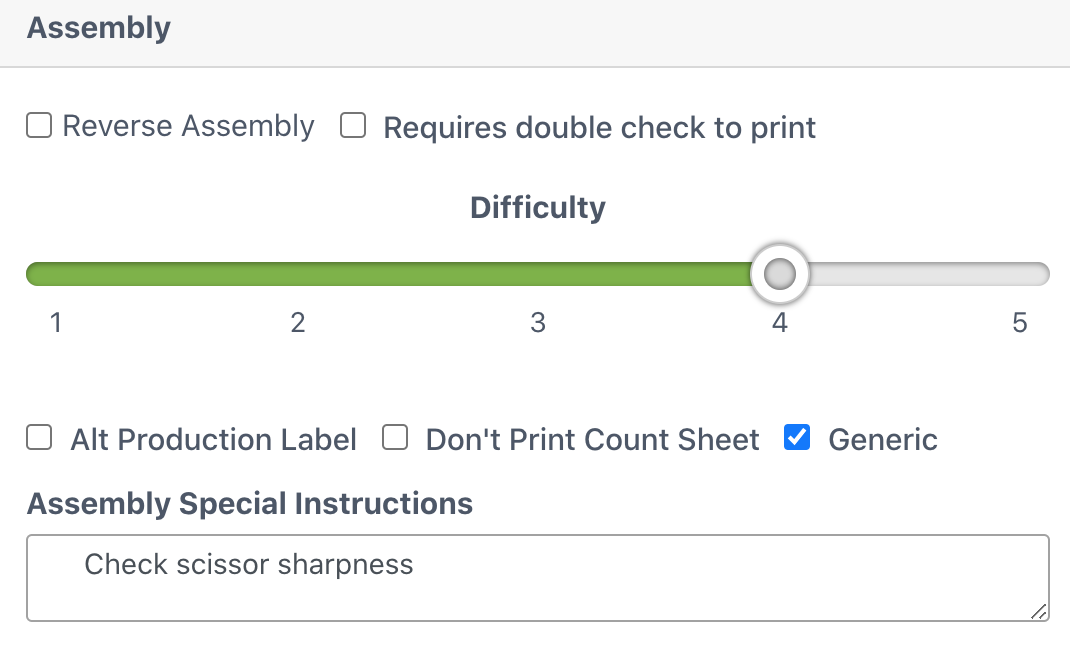

Sterilization Area

This area is used to set sterilization parameters and restrictions when an item is being scanned into a sterilizer.

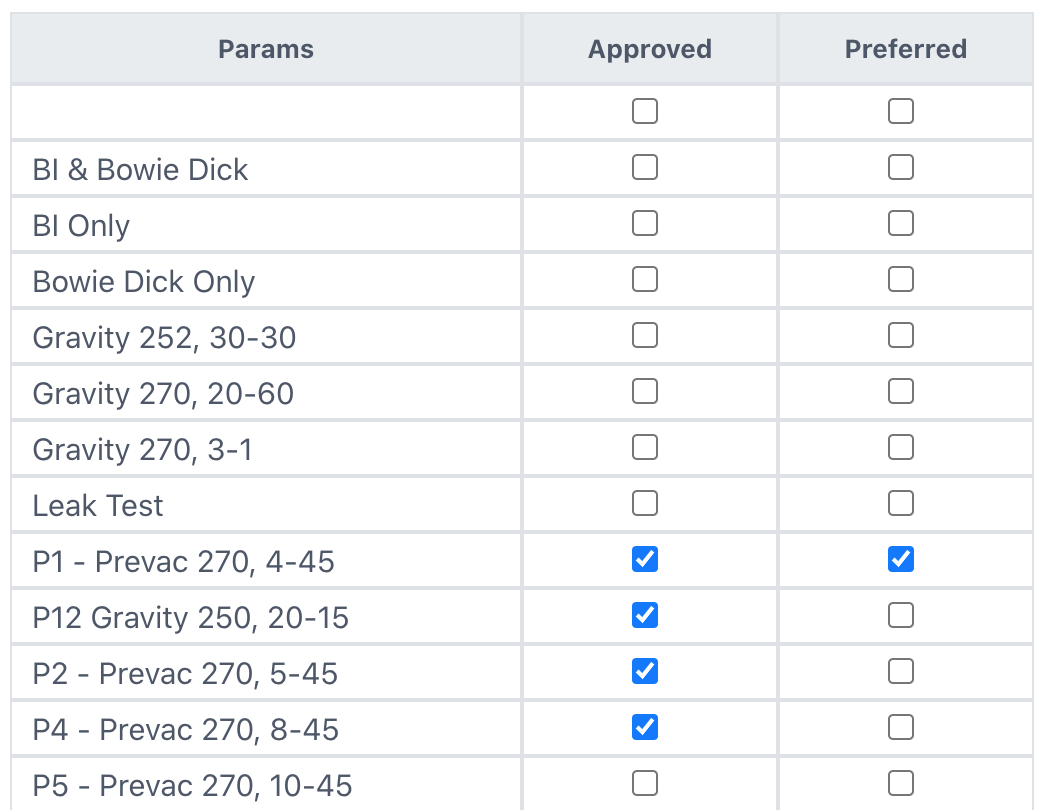

Selecting an approved method will provide a list of params:

Approved

Select the sterilization method and parameters that meet the required sterilization protocol for this item. You can select as many as necessary.

Preferred

Only one method and parameter should be selected as preferred. This designates the ideal sterilization method and parameter settings and will show up on the production labels and during the assembly.